Consult

Consult

In the field of electronic device testing, traditional manual plugging and unplugging methods have long faced multiple challenges. Repeated manual plugging and unplugging is not only time-consuming and labor-intensive, but also causes physical damage to products due to frequent cable replacement at interfaces. This directly leads to low testing efficiency and triggers various faults such as poor contact and interface wear, seriously affecting the stability of the testing process and the accuracy of results. The emergence of flexible automatic plugging and unplugging test modules has completely changed this situation. It realizes the intelligent upgrading of the testing process through automation technology. Compared with traditional methods, it not only makes test data more accurate and avoids manual operation errors, but also maximizes the protection of product interface safety. At the same time, it increases testing efficiency several times, easily coping with various complex testing scenarios. I. Standardized Modular Design: Compatible with Diverse Needs and Enabling Rapid Adaptation

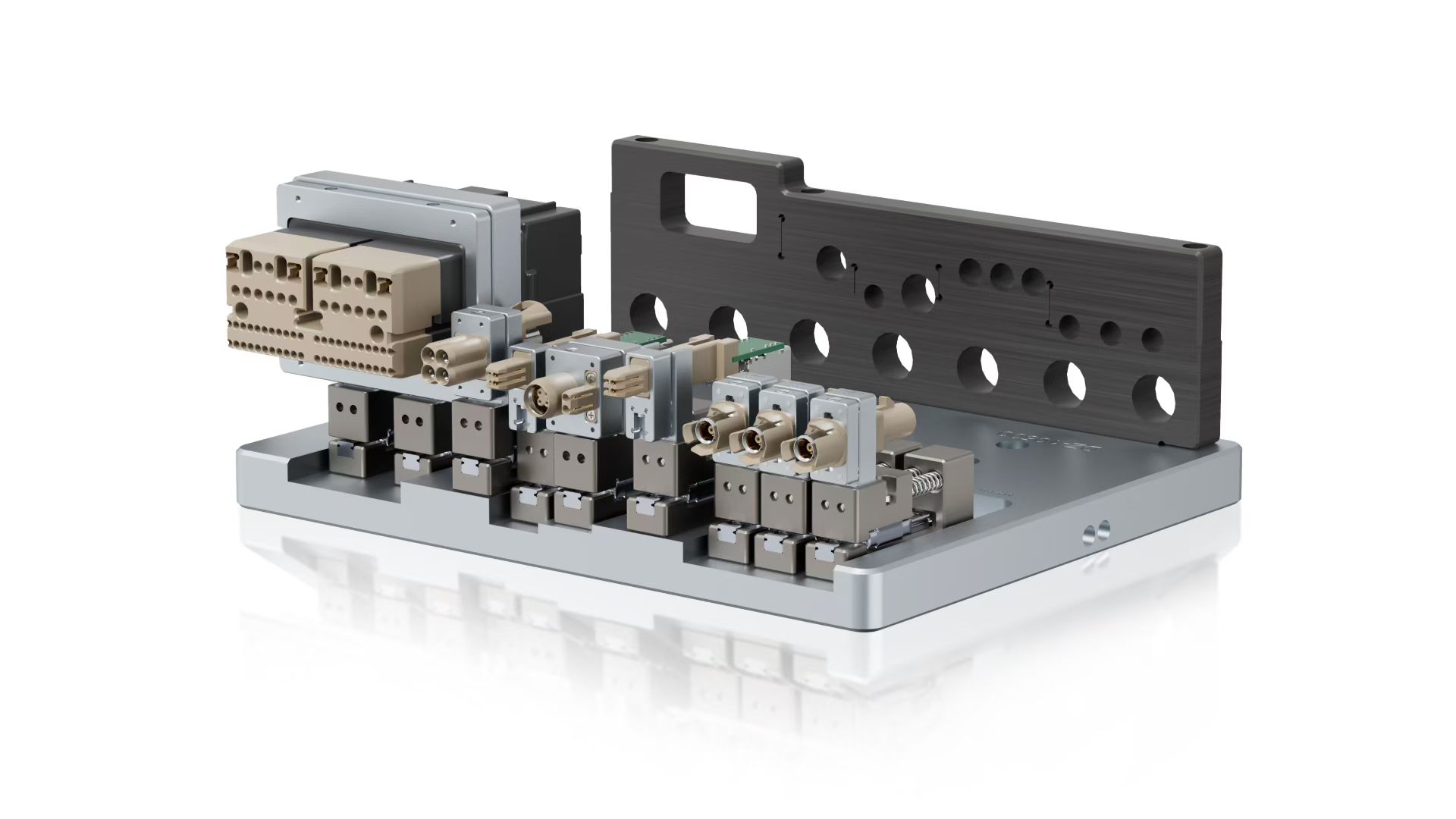

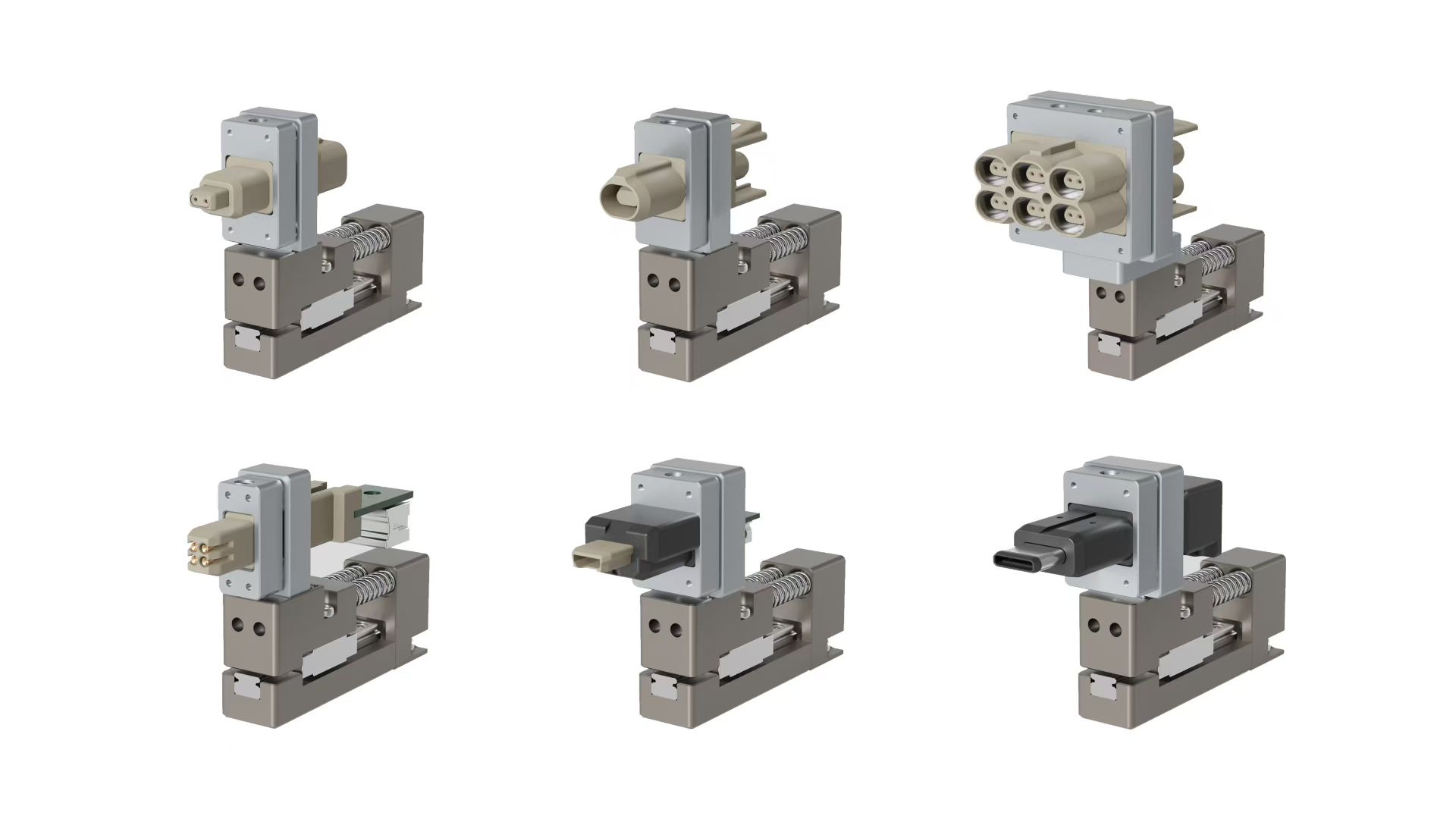

The flexible automatic plugging and unplugging test module adopts an interface-standardized modular architecture, featuring strong compatibility and flexibility, which can cover a variety of mainstream interface types. Whether it is the commonly used pin header, MINI FAKRA, TYPE-C, or USB-4PIN, FAKRA RF interface and Ethernet interface, it can achieve rapid selection and docking without the need to customize separate test solutions for different interfaces.

In terms of operational adaptability, the module supports one-time overall insertion, eliminating the need to dock interfaces one by one, which greatly shortens the test preparation time. At the same time, it is designed with an adaptive floating function for individual interfaces. Even if there is a slight deviation in the interface position, it can achieve accurate docking, avoiding damage caused by forced plugging and unplugging.

In addition, the module has a built-in building block"-style quick-disassembly structure, which fully meets the testing needs of small-batch and multi-category products. When replacing the interface module, no tools are needed; it can be installed and replaced by direct manual plugging and unplugging. The entire process is fast and convenient, effectively reducing equipment downtime.

II. Floating and Buffering Mechanisms: Dual Protection to Prevent Interface Damage

To solve the problems of interface position deviation and uncontrollable plugging force during the testing process, the module is equipped with multiple protection designs to fundamentally avoid product damage.

1. Independent Floating of Interfaces: Accurate Adaptation to Position Deviations

Each test connector is equipped with an independent floating mechanism, which can flexibly absorb the position deviation of the interface in the four directions of up, down, left, and right, with a deviation compensation range of 0.3~0.7mm. Even if there is a slight misalignment in the test product interface, the floating mechanism can automatically adjust the docking angle and position to ensure accurate contact, preventing interface scratches and deformation caused by misalignment.

2. Dual Buffering Structure: Hierarchical Protection to Avoid Overpressure and Overshoot

Primary Buffering (Adaptive Floating Buffering): Through the adaptive floating design, it can absorb errors of 0.3~0.7mm or 0.5~1mm in the up, down, left, and right directions, avoiding "violent plugging and unplugging" caused by inaccurate alignment during the testing process, directly protecting the product interface and test connector, and extending the service life of both.

Secondary Buffering (Front-Rear Stroke Buffering): The bottom of the module is equipped with a dedicated buffer base, which has a buffering function in the front-rear direction and can absorb up to 12mm of front-rear position error. At the same time, the buffer structure is designed with the backward stroke being longer than the insertion stroke, which effectively prevents the over-top phenomenon during plugging and unplugging and avoids damage to internal components caused by excessive extrusion of the product. III. Optimized Detailed Design: Strengthening Guidance and Protection to Improve Operational Safety

The module has been fully optimized in terms of structural details to further ensure the safety and stability of the testing process. Large Chamfer Design at the Front End: The test docking end adopts a large chamfer structure, which not only effectively prevents "jamming" or collision damage to the interface edge when inserting the product, but also has an auxiliary insertion guidance function, helping operators quickly and accurately complete docking and reducing operational difficulty.

Contour Interface Guidance Structure: According to the shape characteristics of different interfaces, a dedicated contour guidance structure is designed to achieve foolproof docking through physical shape matching. This prevents equipment failures caused by reversed or wrong insertion of interfaces and improves docking efficiency at the same time.

Multi-Interface Synchronous Testing Function: It supports simultaneous overall testing of multiple interfaces without the need for batch operations, greatly shortening the duration of a single test. It is especially suitable for batch testing scenarios of multi-interface integrated products (such as smart terminals and industrial controllers), further improving testing efficiency.

IV. Endorsement by Professional Manufacturers: Customized Solutions to Match Exclusive Needs

The above flexible automatic plugging and unplugging test modules are independently developed and produced by Saisheng. As a professional manufacturer focusing on RF shielded boxes, acoustic test chambers, soundproof boxes, and automated test connectors, Saisheng has always been committed to providing "tailor-made" test solutions for customers in different industries.

Whether in the fields of consumer electronics, automotive electronics, industrial control, or communication equipment, Saisheng can customize the interface type, buffer parameters, and test process of the flexible automatic plugging and unplugging test module according to the customer's product characteristics, test standards, and production capacity requirements. This ensures that the solution fully matches the actual application scenario and helps customers achieve the automation and efficiency upgrading of the testing process.

Telephone

Telephone

+86 18038170771

+86 18038170771