Consult

Consult

What Should Be Considered in a shield box Design?

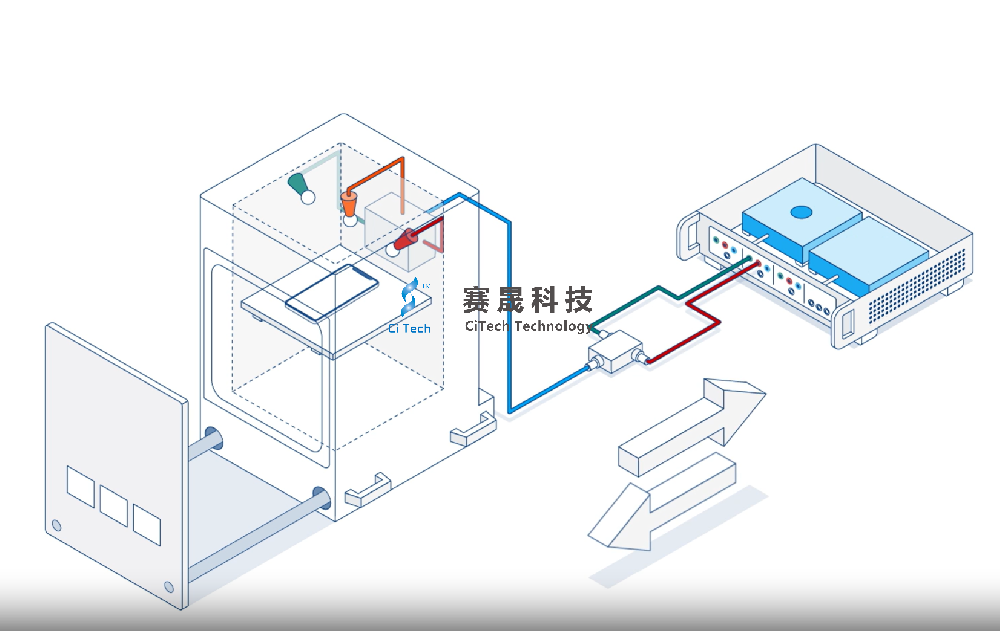

A shield box is a critical component for protecting electronics from electromagnetic interference (EMI). Whether you`re testing wifi module, mobile, or other sensitive devices, the design of your shield chamber plays a vital role in achieving accurate, interference-free results. Here`s what you should consider when selecting or designing the right shield chamber.

1. Material Selection: The Foundation of Shielding

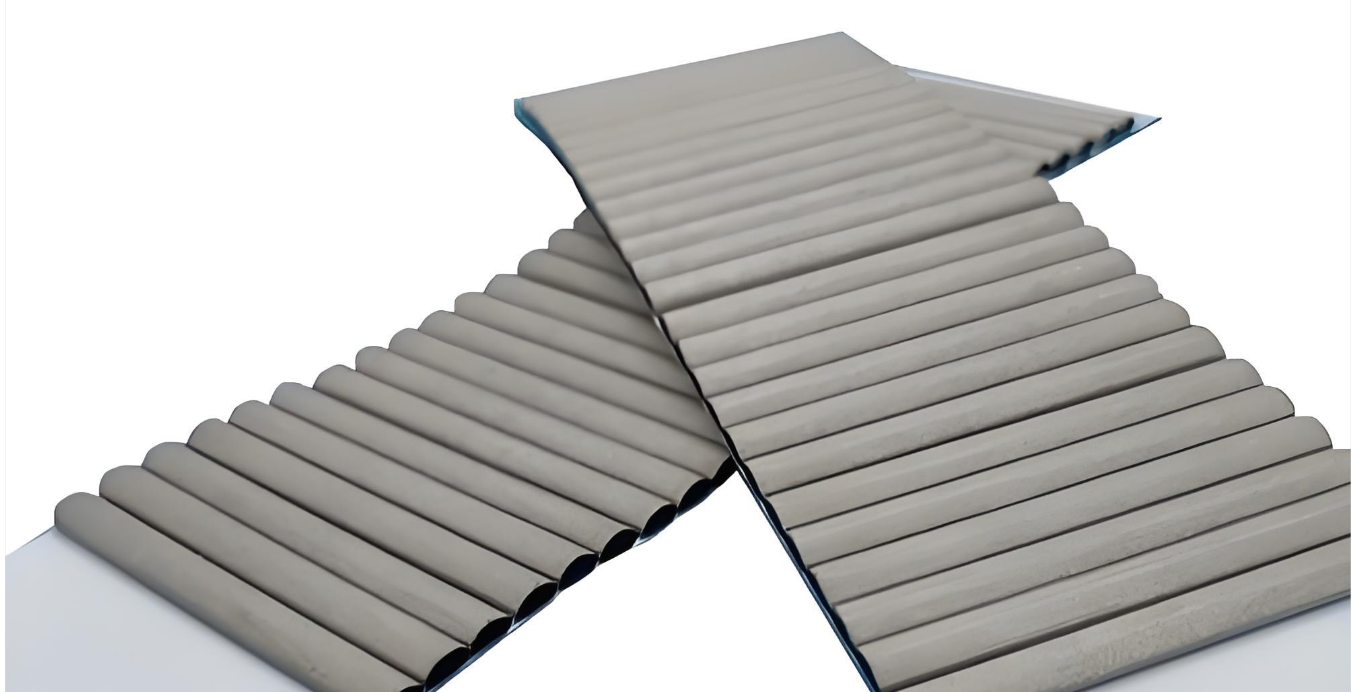

The material used for your shield box directly impacts its effectiveness. Choose conductive materials like copper, aluminum, or stainless steel, which have low electrical resistance. These materials prevent external electromagnetic signals from entering and affecting the test equipment.

When conducting antenna tests on products, the selection of wave-absorbing materials also needs to be taken into account. This is to provide an interference-free testing environment for product antenna tests.

Why It Matters: By selecting the right material, you ensure that the cage blocks interference effectively across the frequency range you need.

2. Size and Shape: Fit for Your Equipment

When designing a shield box, its size and shape should fit the equipment you intend to test. A cage that’s too small can leave gaps, while a cage that’s too large may create uneven shielding. Make sure the cage can fully accommodate your UAV or drone without any interference from external signals.

Pro Tip: For larger items, consider a custom-built shield box to ensure it`s tailored to your testing needs. Saisheng can customize shielded enclosures of various working modes according to your testing requirements.

3. Shielding Effectiveness: Ensure Full Protection

An effective shield box must provide uniform shielding across all relevant electromagnetic spectrums. Test the cage to determine its attenuation levels and confirm it prevents unwanted signals from leaking in.

How to Improve Effectiveness: Conduct testing to ensure the shielding works well across low to high-frequency ranges, particularly for UAV testing, which might involve a broad spectrum of signals.Saisheng provides shielded enclosures with excellent shielding performance, and the maximum shielding effectiveness can reach over 100 dB.

4. Ventilation and Access: Balancing Shielding and Usability

Although the cage should block signals, it must also offer sufficient ventilation to prevent overheating. When testing electronics, especially sensitive equipment like drones, maintaining airflow is essential. Additionally, provide access points for monitoring and controlling tests without compromising the cage’s integrity.

Ensure Ease of Access: Design the box with doors or panels that allow you to easily introduce testing equipment or adjust settings without weakening the shield.

5. Grounding and Bonding: A Vital Safety Step

Proper grounding ensures the shield box doesn`t accumulate static electricity, which could damage sensitive equipment. Grounding the cage connects it to the earth, allowing safe discharge of electrical buildup.

Why Grounding Matters: Without proper grounding, the Faraday cage could become a source of interference itself, negating its shielding benefits.

6. Door and Seal Integrity: No Leaks Allowed

The door or access point of a shield box must form a tight seal to maintain its shielding. Use magnetic or conductive gaskets to ensure a seamless fit. Even the smallest gap could allow external signals to penetrate the shield.

Tip for Success: Check that the door`s seal holds up under varying pressure or temperature conditions to ensure consistent performance during testing.

7.Filtered interfaces — select the appropriate filtered interfaces according to your needs. Saisheng offers a wide range of filtered interfaces for your selection. such as USB2.0, USB3.0, DC, AC, N / SMA, RJ45, DB9 ,DB 15,DB25, HDMI,ect.

8.Customization for Your Testing Needs

Finally, consider whether your testing needs require a custom shield box. Standard designs may not offer the right fit for your equipment or specific test requirements. For testing complex systems, like UAVs, you may need to customize the chamber`s design for optimal results.

Conclusion: Choosing the Right shield box for Accurate Testing

Incorporating the right materials, size, shielding, and grounding techniques ensures your shield box delivers reliable and consistent results. The design of your cage will directly impact the accuracy of your testing, whether you`re evaluating UAV performance or conducting regulatory compliance checks.

For more information on choosing the best shield box for your needs, visit our Shielding Solutions Page.

Telephone

Telephone

+86 18038170771

+86 18038170771