Consult

Consult

In the modern manufacturing landscape, an increasing number of products rely heavily on exceptional acoustic quality to stand out in the market. Beyond speaker systems, car engines, and air conditioners, devices like household fans need to operate with a gentle breeze sound instead of a harsh whir, and medical equipment such as ultrasound machines must produce clear, consistent acoustic signals to ensure accurate diagnoses. For manufacturers of these products, an acoustic test chamber is not just a facility but a critical tool to guarantee product performance. Every acoustic test chamber is designed to create a controlled environment, and paired with an acoustic box, it forms a comprehensive testing setup. The acoustic box acts as a supplementary component, often used to house small parts of the product during testing, ensuring that even tiny sound emissions are captured accurately.

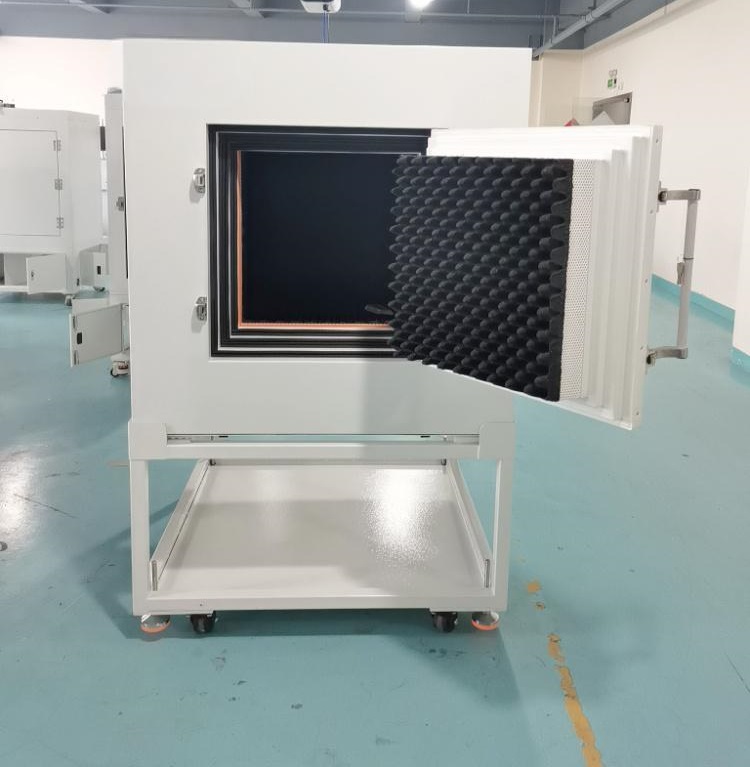

An acoustic test chamber is built with multiple layers of sound - absorbing and sound - insulating materials. These materials work together to block external noises, such as the hum of factory machinery or the honking of cars outside, from entering the chamber. Inside the acoustic test chamber, the walls, ceiling, and floor are covered with specialized foam or fiberglass panels that minimize sound reflections. This design is crucial because any reflected sound could interfere with the accuracy of the acoustic measurements. Similarly, an acoustic box also adopts sound - dampening technologies. It is often used when testing small components of a product, like a tiny motor in a toy, as it can isolate the component's sound from the surrounding environment within the acoustic test chamber.

Another key feature of an acoustic test chamber is its integrated noise analysis system. This system includes high - precision microphones that capture the sound emitted by the product being tested. The microphones are connected to a computer that processes the sound data, providing detailed information such as the sound pressure level, frequency spectrum, and noise duration. This data helps manufacturers identify any acoustic defects in the product, such as an unexpected rattle in a washing machine or a distorted sound in a headphone. An acoustic box can also be equipped with a 小型 noise analysis module. When testing a small part, the module in the acoustic box can focus on the specific sound characteristics of that part, making it easier to detect minor defects that might be overlooked in the larger acoustic test chamber.

Manufacturers across various industries depend on the acoustic test chamber and acoustic box to maintain high product standards. For example, in the automotive industry, engineers use an acoustic test chamber to test the sound of a car's exhaust system, ensuring it meets regulatory noise limits. They also use an acoustic box to test small parts like window regulators, making sure their operation is quiet. In the electronics industry, an acoustic test chamber is used to test the sound of laptop fans, and an acoustic box is used to test the speakers in smartwatches. Without the acoustic test chamber and acoustic box, it would be nearly impossible for manufacturers to consistently produce products with reliable acoustic quality. Every acoustic test chamber and acoustic box.

Telephone

Telephone

+86 18038170771

+86 18038170771